Introduction

Busbars are the backbones for most power applications, providing the critical interfaces between the power module and the outside world. This has remained true even throughout the continuing design iterations that have occurred over the past few decades, during the evolution of the power, motor, industrial and automotive industries.

With the need to conduct substantial amounts of current in such applications continuing to grow, busbars are destined to be a mainstay in electrical power distribution going forward, while also evolving to meet changing application requirements.

In this post, we explore what busbars are and how the integration of busbar functionality is undergoing significant change as power applications become smaller, faster and more complex.

What Are Busbars

Busbars are sophisticated pieces of technology that make complicated power distribution easier, less expensive and more flexible.

In power-intensive electrical applications, a busbar (often also spelled bus bar or bussbar) is a critical element for conducting significant current levels between functions within the assembly. Busbars may be used in any number of configurations, ranging from vertical risers to bars within a distribution panel, or part of an industrial process.

Typically, they are a strip, a bar or sometimes a tube made of copper, brass or aluminum optimized for the application’s electrical current requirements and performance specifications. While busbars primarily perform electrical rather than structural functions, designers always need to consider how busbars mesh within electrical performance and form factor constraints, as well as ensuring that specified heat dissipation parameters are met.

Busbar Functionalities

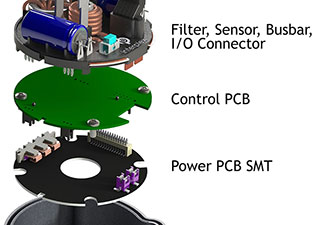

As industries trend towards more electrification in transportation, mobility and renewable energy, it becomes more critical that power modules, used for inversion or conversion, become more efficient. To maximize efficiency, busing the power into and out of the power inversion circuit becomes a critical element that must be incorporated into the overall system design.

For example, to improve efficiency in high voltage applications, DC link busbar designs must minimize stray inductance to minimize voltage spikes to allow for faster switching speeds. Design elements like short currents paths, matched currents paths, and closely stacked tolerance busbars become critical design elements for the overall system performance.

This is where multi-layer laminated, overmolded insulated bus systems are needed to support the power module system.

In Low Voltage Systems, package size often becomes the most critical design path. In these systems, the integration of capacitors, inductors, coils into the overall bus system helps to create a more compact form factor that allows designers to integrate the overall power module system as parts of the motor powertrain.

Copper bus systems like the DC-link bus systems in inverters maximize high current transmission, minimize power losses and provide a high level of heat transfer. However, connecting the busbar systems to other components like DC-link capacitors or to the input of the power module has, up until recently, been a difficult process.

The conventional methods used in larger power applications, such as bolting, welding, or clamping connections to busbars, are not always feasible as new-generation power applications become smaller and more complex.

Soldering is also problematic because a busbar’s heat dissipation may make soldering impractical as part of mainstream automated assembly processes and often requires specialized secondary manual soldering steps. Not only is this time-consuming and costly, the exposure of populated sub-assemblies to the heat of secondary soldering processes can risk damage to sensitive components.

Press-Fit for Busbar Interconnects

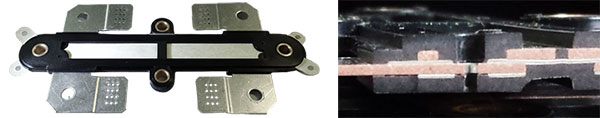

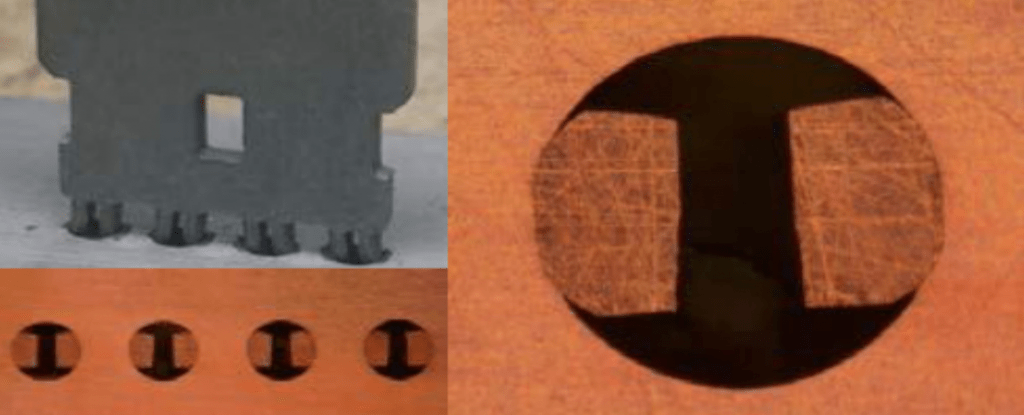

Solderfree interconnects, such as Press-Fit technology, offer a straightforward solution to these issues because they provide excellent conductivity and eliminate the need for soldering.

Until recently, some designers have been hesitant to adopt Press-Fit technology to connect directly with copper busbars because of a misconception that at high temperatures, the copper creep (or its tendency to move slowly and deform permanently) may weaken the interconnects over time and degrade overall performance.

As pioneers in Press-Fit and leaders in busbar applications, at Interplex, we have conducted extensive testing on our Press-Fit interconnects in copper busbars, including accelerated creep testing at high temperatures that allay these fears. These tests have shown the interconnects to be well-suited for implementing busbar interfaces that can deliver reliable performance over extended product lifecycles.

Overall, it can be said that the full integration of busbars within power applications by using pluggable Press-Fit technology can significantly improve power efficiency, reduce the bill-of-material costs, decrease assembly complexity and shrink the overall physical size of the power assembly.

Busbar Capabilities and Industries We Serve

Here at Interplex, we provide key enabling technologies that streamline the assembly and improve the efficiency of new generation power stack inverter systems.

As part of our global leadership in the power module industry, we are primarily focused on providing module makers with power lead frames, high current busbar interfaces, Press-Fit solderless interconnects and integrated packaging solutions.

In addition, we have been leading the industry in the development of new and innovative busbar technologies, such as the Laminated Busbar and Flexible Busbar designs described in the following sections.

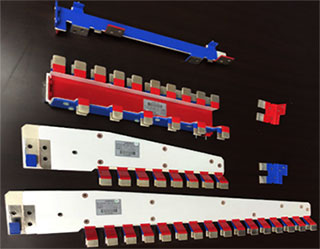

Laminated Busbars

Laminated busbar technology consists of a multi-layer composite structure connected with a platoon, which can be regarded as similar to a highway distribution system. In contrast to traditional, time-consuming and cumbersome wiring methods, the use of the laminated busbar approach provides modern, easy to design, quick to install, and well-structured distribution systems. It is characterized by repeatable electrical performance, low impedance, anti-interference, good reliability, space-saving, as well as simple and quick assembly.

Laminated busbars are widely used in the following applications:

- Power and hybrid traction

- Power traction equipment

- Cellular communication

- Base stations

- Telephone exchange systems

- Large network equipment

- Large and medium computers

- Power switch systems

- Welding systems

- Military equipment systems

- Power generation systems

- Power conversion modules of electric equipment

Flexible Busbars

Flexible busbar designs consist of copper foils tightly diffusion welded at the mounting areas, which enables the ends to be rigid for connections while keeping the middle flexible.

Benefits of Interplex flexible busbars:

- Excellent vibration and shock absorption

- Improves electrical conductivity

- Increases power efficiency

- Maintains flexibility without compromising mounting strength or vibration absorption

- High tolerance for assembly mismatch/offset

- Easily customizable for compatibility with specific assembly environments

Examples of flexible busbar applications include:

- Electric, Hybrid and Fuel Cell vehicles

- Electrical connections in switching cabinets

- Power link for generators

- Transformers

- Charging stations

Summary

While busbars continue to be a critical factor for carrying current within and between sophisticated power assemblies and applications, the underlying technologies and design approaches for implementing busbars have seen a quiet revolution in new capabilities.

For product engineers who need to implement the most cost-effective, reliable and adaptable busbar technologies into new designs, it is very important to look toward partnering with specialists that can provide a full range of implementation options.

With the development of new busbar technologies, engineers no longer need to adapt their designs to fit a few limited busbar approaches, but rather can choose from a variety of busbar technologies to best fit their specific designs.

A critical factor for success with using new busbar technologies is to start early in the design process by working with a knowledgeable partner that can advise on a variety of approaches and can provide the best technology choice, along with the ability to support the design, prototype and production ramp-up phases of your product launch.