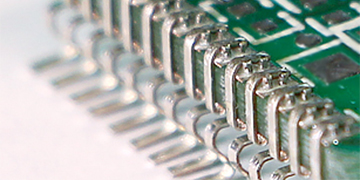

Solder and Flux Bearing Technology

Interplex’s Solder and Flux Bearing Technology eliminates costly and defect prone soldering methods, such as hand or wave soldering by pre-depositing precise amount of solder and flux to each contact lead. An alternative for Press-Fit, this removes limitations to intrusive reflow.

Our Solder and Flux Bearing connectors are soldered using conventional SMT equipment and processes, without any additional solder, solder paste or flux. As we continue developing our technology, we aim to transition PCB assemblies requiring hand labor and/or multiple soldering processes to a streamlined single or double sided reflow process.

Through Hole Connectors

Solder and Flux Bearing is widely used for through hole connectors of various applications. Discover our connectors ranging from DIN 41612 to PCMIA & CompactFlash.

• Self-soldering, RoHS Compliant

• Self-soldering

Solder and Flux Bearing is widely used for through hole connectors of various applications. Discover our connectors ranging from DIN 41612 to PCMIA & CompactFlash.

• Self-soldering, RoHS Compliant

• Self-soldering

PC104 and PC104 Plus Connectors

The PC104 bus is fast becoming the embedded computing industry standard, with the PC104 Plus designed for high speed PCI bus in embedded applications.

• Self-soldering, RoHS Compliant

• Self-soldering

The PC104 bus is fast becoming the embedded computing industry standard, with the PC104 Plus designed for high speed PCI bus in embedded applications.

• Self-soldering, RoHS Compliant

• Self-soldering

Edge Mount Headers

Designed for memory modules, hybrid circuits and high-speed PCB to PCB connection, these connectors require precise amount of solder and flux for each lead attachment.

• Self-soldering

Designed for memory modules, hybrid circuits and high-speed PCB to PCB connection, these connectors require precise amount of solder and flux for each lead attachment.

• Self-soldering

Product Drawings

Discover Interplex Solder and Flux Bearing Technology with the available product drawings below. You may view the information online, downloaded or printed.Through Hole Connectors, Self-soldering, RoHS Compliant

DIN 41612

- Solder and Flux Bearing, 96 Position, DIN 41612 Male Connector Part No.: SDMS-3324X-X-000 | Ref.: S20613

- Solder and Flux Bearing, 48 Position, DIN 41612 Male Connector Part No.: SDMS-316HX-N-000 | Ref.: S20712

- Solder and Flux Bearing, 30/48/96 Position, DIN 41612 Male, Right Angle Connector Part No.: TDMR3XXXAXX-00 | Ref.: S21310

Header

- .100 [2.54] Solder and Flux Bearing Header, Dual Mate Part No.: HCXXXXXXXX-XXXD-00 | Ref.: S20566

- .100 [2.54] Solder and Flux Bearing Header Part No.: HCXXXXXXX-XXX-00 | Ref.: S20556

- .100 [2.54] Solder and Flux Bearing Header, Reverse Mate Part No.: HCXXXXXXX-XXX-R00 | Ref.: S20629

- .100 [2.54] Solder and Flux Bearing Header, High Volume Part No.: HCXXXXXXX-XXX-H0 | Ref.: S20567

- .100 [2.54] Solder and Flux Bearing Header, Reverse Mate, Trimmed Part No.: HCXXXAXXX-XXX-RZ0 | Ref.: S20720

- .100 [2.54] Solder and Flux Bearing Stacked Header Part No.: HC207EB467N075-A | Ref.: S20617

- .100 [2.54] Solder and Flux Bearing Header, Right Angle Part No.: HRXXXX-1X-XX-00 | Ref.: S20559

- .100 [2.54] Solder and Flux Bearing Header, Right Angle Part No.: ZRXXXX1XX-XX-00 | Ref.: S20554

- .100 [2.54] Solder and Flux Bearing Header Part No.: HRXXXX1XX-0X-NW | Ref.: S20717

- .100 [2.54] Solder and Flux Bearing Header, Right Angle, High Volume Part No.: HRXXXA1BB-XX-HO | Ref.: S20564

- .100 [2.54] Solder and Flux Bearing Header, Shrouded Right Angle Part No.: SRC2XX425X126-0 | Ref.: S20604

- .100 [2.54] Solder and Flux Bearing Header, Shrouded Right Angle Part No.: SRC2XX4250126-0 | Ref.: S20716

- .100 [2.54] Solder and Flux Bearing Header, Shrouded Vertical Part No.: SVC2XXB462X130-HO | Ref.: S20551

- .100 [2.54] Solder and Flux Bearing Header, Shrouded Vertical Part No.: SVC2XXX405X123-0 | Ref.: S20608

- .100 [2.54] Solder and Flux Bearing Header, Shrouded Vertical Part No.: SVC2XXX405X538-0 | Ref.: S20821

- .100 [2.54] Solder and Flux Bearing Header, Shrouded Vertical Part No.: SVC2XXX3580135-0 | Ref.: S20715

- .100 [2.54] Solder and Flux Bearing Stacked Header Part No.: HCXXXXXXXXXXXX-0 | Ref.: S20565

- .100 [2.54] Solder and Flux Bearing Stacked Header Part No.: SCXXXXXXXXXXXX-0 | Ref.: S20562

- .100 [2.54] Friction Lock, Solder and Flux Bearing Header Part No.: FLCVXXXXXXX-00 | Ref.: S20630

- .100 [2.54] Solder and Flux Bearing Header Part No.: ZCXXXXXXX-XXX-00 | Ref.: S20612

- 2mm Solder and Flux Bearing Header Part No.: ZMXXXXXXX-XXX-00 | Ref.: S20702

- 2mm Solder and Flux Bearing Header, High Volume Part No.: HMXXXXXXX-XXX-HO | Ref.: S20557

- 2mm Solder and Flux Bearing Stacked Header Part No.: HMXXXXXX-XXX-00 | Ref.: S20552

- 2mm Solder and Flux Bearing Header Part No.: HMXXXXXX-XXX-00 | Ref.: S20553

- 2mm Solder and Flux Bearing Header, Shrouded Vertical Part No.: SVMZXXP340X130-HO | Ref.: S20550

- 2mm Solder and Flux Bearing Stacked Header Part No.: HMXXXXXXXXXXXXX-0 | Ref.: S20555

- 2mm Solder and Flux Bearing Header, Right Angle Part No.: RMXXXA1XB-XX-00 | Ref.: S20611